Filter Mesh Fabric

Description

Description

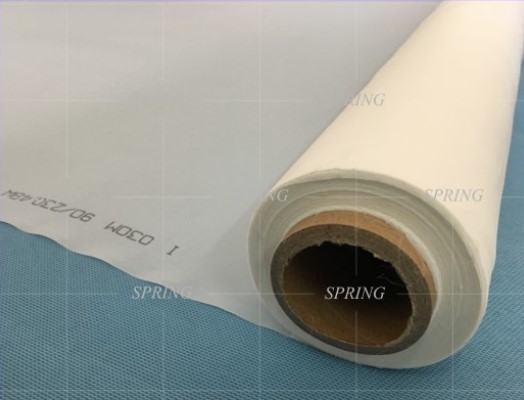

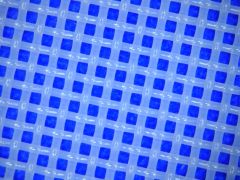

100% nylon monofilament filter mesh

| Introduction: Nylon filter cloth: nylon mesh also called Polyamide mesh, is woven mesh made from 100% nylon monofilament yarn. Nylon mesh good wear resistance, tensile strength, elongation and flexibility. The use temperature of nylon can up to 120℃. The heat setting temperature is more than 120℃. Good Alkali-resistance, second only to carbon tetrafluoride fiber. But nylon filter cloth is not acid-resistance, the nylon filter mesh will reacted and dissolved once meet concentrated sulfuric acid, hydrochloric acid. Susceptible to oxidant oxidation, under high temperature or high concentration of oxidant, the oxidation rate quickly. Nylon filter cloth can be dissolved in organic solvents such as phenol or concentrated formic acid. Shanghai SPRING PA nylon mesh filter fabric is widely used for the air, liquid, solid and powder filter, such as: milk, coffee, tea, water filter, etc. It can be produced into different shapes, such as bags, discs, belt, etc. under your request. |

|

Specification:

| Type | Weave | Mesh/CM | Mesh/inch | Wire Dia.(um) | Mesh Opening(um) | Open Area (%) |

Thickness (um) |

|---|---|---|---|---|---|---|---|

| PA-4/1950 | PW | 4 | 10 | 550 | 1950 | 61 | 1096 |

| PA-5/1500 | PW | 5 | 13 | 500 | 1500 | 56 | 998 |

| PA-6/1267 | PW | 6 | 15 | 400 | 1267 | 58 | 796 |

| PA-7/1079 | PW | 7 | 18 | 350 | 1079 | 57 | 691 |

| PA-8/900 | PW | 8 | 20 | 350 | 900 | 52 | 697 |

| PA-9/861 | PW | 9 | 24 | 250 | 861 | 60 | 492 |

| PA-10/750 | PW | 10 | 25 | 250 | 750 | 56 | 494 |

| PA-12/533 | PW | 12 | 30 | 300 | 533 | 41 | 590 |

| PA-14/514 | PW | 14 | 35 | 200 | 514 | 52 | 391 |

| PA-16/425 | PW | 16 | 40 | 200 | 425 | 46 | 393 |

| PA-18/356 | PW | 18 | 45 | 200 | 356 | 41 | 395 |

| PA-20/300 | PW | 20 | 50 | 200 | 300 | 36 | 396 |

| PA-24/267 | PW | 24 | 60 | 150 | 267 | 41 | 292 |

| PA-28/207 | PW | 28 | 70 | 150 | 207 | 34 | 295 |

| PA-30/213 | PW | 30 | 76 | 120 | 213 | 41 | 230 |

| PA-32/213 | PW | 32 | 80 | 100 | 213 | 46 | 186 |

| PA-36/178 | PW | 36 | 90 | 100 | 178 | 41 | 189 |

| PA-40/150 | PW | 40 | 100 | 100 | 150 | 36 | 192 |

| PA-44/127 | PW | 44 | 110 | 100 | 127 | 31 | 195 |

| PA-48/128 | PW | 48 | 120 | 80 | 128 | 38 | 150 |

| PA-56/119 | PW | 56 | 142 | 60 | 119 | 44 | 96 |

| PA-59/109 | PW | 59 | 150 | 60 | 109 | 42 | 110 |

| PA-64/96 | PW | 64 | 163 | 60 | 96 | 38 | 116 |

| PA-72/89 | PW | 72 | 183 | 50 | 89 | 41 | 90 |

| PA-80/75 | PW | 80 | 203 | 50 | 75 | 36 | 93 |

| PA-88/71 | PW | 88 | 224 | 43 | 71 | 39 | 70 |

| PA-96/61 | PW | 96 | 244 | 43 | 61 | 34 | 74 |

| PA-100/57 | PW | 100 | 254 | 43 | 57 | 32 | 75 |

| PA-104/53 | PW | 104 | 264 | 43 | 53 | 31 | 76 |

| PA-110/48 | PW | 110 | 280 | 43 | 48 | 28 | 78 |

| PA-120/40 | PW | 120 | 305 | 43 | 40 | 23 | 80 |

| PA-130/34 | PW | 130 | 330 | 43 | 34 | 19 | 83 |

| PA-140/33 | PW | 140 | 355 | 38 | 33 | 22 | 73 |

| PA-150/28 | TW | 150 | 380 | 39 | 28 | 17 | 75 |

| PA-157/25 | TW | 157 | 400 | 39 | 25 | 15 | 76 |

| PA-165/30 | TW | 165 | 420 | 30 | 30 | 25 | 54 |

| PA-200/21 | TW | 200 | 500 | 30 | 21 | 17 | 56 |

| PA-240/3 | TW | 240 | 600 | 39 | 3 | 0.5 | 68 |

The following points should be noted for nylon mesh usage:

- Because the nylon mesh is more elongation than polyester, therefore it needs increase the stretching tension to make sure no problem happened during screen printing.

- Non acid resistance, therefore be careful about the acid, formic acid and other erosion.

- Avoid light for the nylon mesh stock as UV light has little impact on the mesh.

How to choose screen printing mesh?

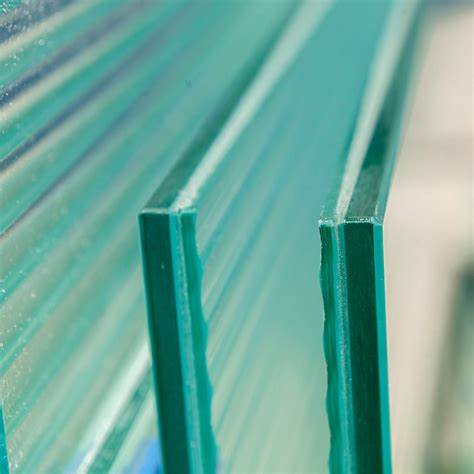

- According to the types of the substrates. Such as fiber fabric, paper products, glass, ceramics, metal, plastic, wooden, electronics, etc.

- According to the ink natures to choose the screen printing mesh, different ink have different characteristics. So we have to consider the ink drying time and color sharpness, the substrates absorb ink ability, etc.

- Different screen printing mesh material has different performance, according to different adaptability to select the appropriate screen.

The issues we should to notice when we select the screen printing mesh:

- If the substrate surface is rough, usually choose low count nylon screen printing mesh.

- If the patterns with fine lines, usually high count screen mesh is needed.

- Screen printing mesh also need to consider the cost, under meet the screen printing requirements, lower prices screen printing mesh is more good choice. SPRING PA and SPRING SDW are good choice. As under same quality, these meshes have cheaper price.

Our offer your benefit:

- 10mesh to 600mesh can be provided under your request, 350mesh above is twill weave

- Width from 30cm to 330cm can be provided

- Different colors can be produce under your order

- Fast delivery time Excellent service Quality assurance

Features:

- Smooth surface

- Good ink permeability

- Large viscosity and particle size ink can be used, to make sure the fine patterns printing.

- Good elasticity, suitable softness, good adaptability to the substrate, good use for convex and curved surface product’s screen printing.

- Good tension strength

- Wear resistance

- Long service life

- Alkali-resistance

- Renewable usage

- Anti-static

Send your message to us