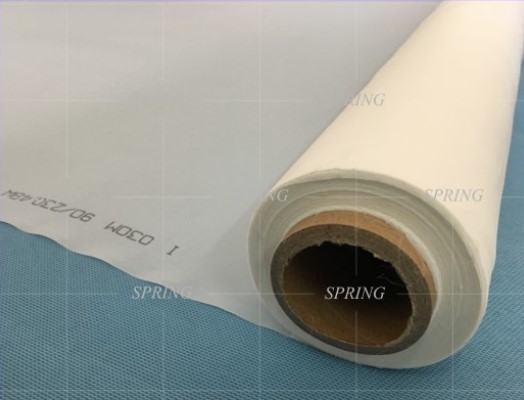

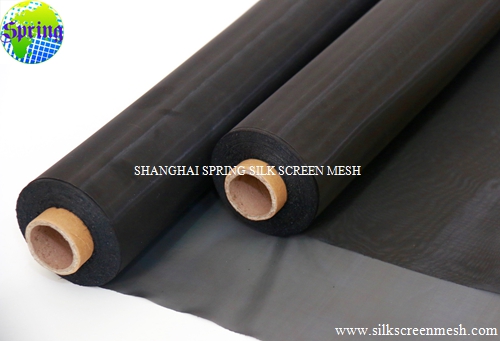

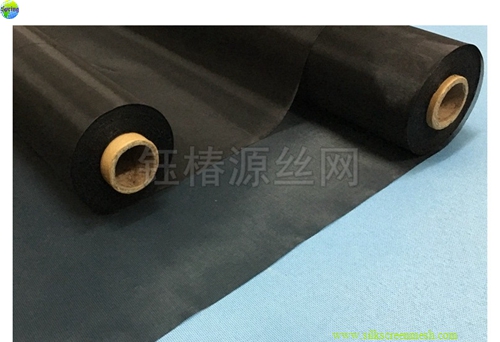

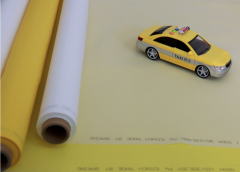

Polyester Screen Printing Mesh

SPRING Polyester screen printing mesh has the following advantages in the printing industry:

-

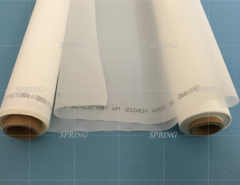

Strong wear resistance: Compared to other types of printing screens, polyester printing mesh is more durable and less prone to damage.

-

High precision: Polyester printing mesh has a very fine and uniform distribution of mesh openings, which provides higher printing precision and color reproduction.

-

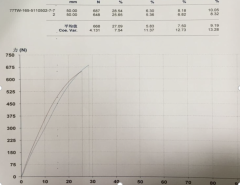

Excellent tensile strength: Due to the sturdy material structure of polyester printing mesh, it has excellent tensile strength, which can prevent printing distortion caused by elongation or deformation of the printing screen.

-

Good chemical resistance: Polyester printing mesh has good resistance to chemical agents and water, making it more stable and durable during the printing process.

-

Reusability: Polyester printing mesh can be reused dozens of times and is very convenient for cleaning, maintenance, and storage, which makes it cost-effective and reduces environmental pollution.