Screen Printing Related machine

Description

Description

China supplier factory price Ultrasonic Welding Machine

| Introduction: Shanghai SPRING Ultrasonic Lace Machine is welding for chemical fiber fabrics, chemical fiber leather products, PE film, etc.. This electrical equipment brings in the latest international ultrasonic circuit, and after improvement, Basic components: 1. New type PC intellectual ultrasonic generator; 2. 20KHz ultrasonic transducer unit; 3. Bottom mould fixed suspension structure; 4. Single-motor speed adjustment system; 5. Manual roller lifting system; |

|

Advantages:

- The output power is strong and steady, suitable for long time continuous working.

- The ultrasonic power can be adjusted randomly, satisfying the welding requirement of different fabrics and materials.

- Double circuit Intelligent Protection System ensures the safety of the main part of the machine, avoiding the damage of main part’s electric circuit which is caused by user’s improper adjustment or usage.

- The design of the appearance is elegant and compact, conforming to the international trends. The ultrasonic frequency regulator adopts the panel hidden type, which is convenient for customer to adjust the ultrasonic frequency and avoid the improper random adjustment.

Characteristics:

1. Built-in PC chips, multi-circuit ultrasonic protection system to make the machine run safely;

2. Strong ultrasonic power with three adjustable gears (maximum, medium and minimum), meets the welding requirements of different materials andthicknesses;

3. The performance of the machine reaches international level with automatic frequency tracking system and ultrasonic soft-starting technology;

4. Variety of roller patterns, other roller designs available according to customer requirements;

5. Four times faster than sewing machines, minimal operator training required.

Functions:

1. Trimming: Straight or curvilinear edge cutting and edge treatment for melting,so smooth, no rough edges;

2. Sealing: Two or more layers of fabric stitched together without thread replacing the sewing needles, good welding strength;

3. Hole making: Cut out the various patterns of holes, and treatment of side melting;

4. Slitting: Single or more cutting of the material at the same time, and treatment of side melting without burr;

5. Forming: Simultaneous cutting,sealing and embossing to make production in one time.

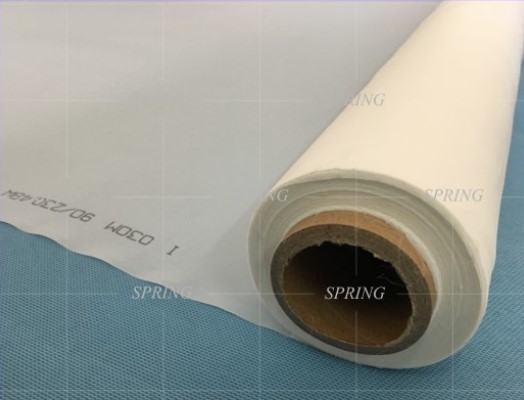

Suitable material:

All kinds of artificial, leather and fabric, nonwoven fabric, spun-bonded cotton, thermoplastic film, chemical plastic piece, such as nylon, polyester, ABC, PC, PU, PE, PP, PS, etc.

Send your message to us