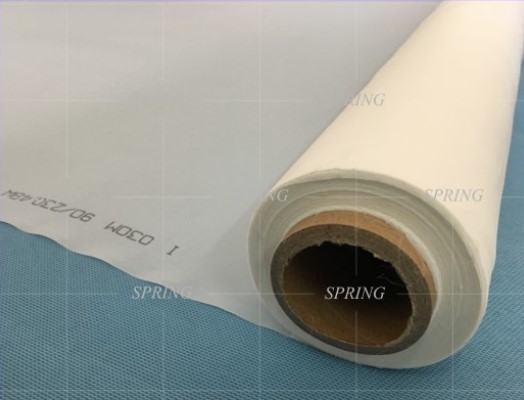

Polyester Screen Printing Mesh

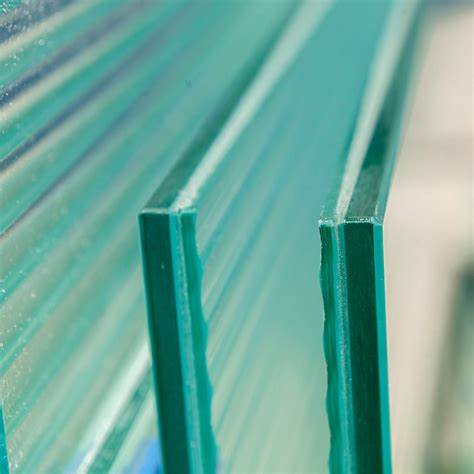

High tension Bolting Cloth 100% monofilament polyester Screen Printing Mesh for Glasses

| Introduction: From the tradition glass screen printing to the emerging LED, touch panel printing, silk screen printing technology throughout the whole glass industry and play a pivotal role. As the glass have great diversity, the glass printing requires a practical and efficient printing method for decoration and application. Our SPRING screen printing mesh has high reproducibility and quality can provide you more clearly economic advantages. They accelerate the production of stencils and optimize the printing process. SRING SDW screen printing mesh can be used in the largest range of different screen printing mesh types. This mesh is the best stencil carrier for an almost infinite number of screen printing applications. Application: Display windows screen printing, Automotive glass screen printing, Architectural glass screen printing, mosaic glass screen printing, Home Application glass screen printing, Hollow Ware glass screen printing, etc. |

|

Specification:

| Type | Mesh/CM | Mesh/inch | Wire Dia.(um) | Mesh Opening(um) | Open Area (%) |

Thickness (um) |

|---|---|---|---|---|---|---|

| DPP32/100 | 32 | 80 | 100 | 213 | 46 | 200 |

| DPP34/100 | 34 | 86 | 100 | 194 | 44 | 221 |

| DPP36/100 | 36 | 90 | 100 | 178 | 41 | 216 |

| DPP40/80 | 40 | 100 | 80 | 170 | 46 | 150 |

| DPP43/80 | 43 | 110 | 80 | 153 | 43 | 130 |

| DPP47/71 | 47 | 120 | 71 | 142 | 44 | 135 |

| DPP53/64 | 53 | 135 | 64 | 125 | 44 | 120 |

| DPP59/64 | 59 | 150 | 64 | 105 | 39 | 120 |

| DPP62/64 | 62 | 155 | 64 | 100 | 37 | 115 |

| DPP64/64 | 64 | 163 | 64 | 92 | 35 | 120 |

| DPP68/64 | 68 | 173 | 64 | 83 | 32 | 130 |

| DPP72/55 | 72 | 183 | 55 | 84 | 37 | 100 |

| DPP77/55 | 77 | 195 | 55 | 75 | 33 | 105 |

| DPP90/48 | 90 | 230 | 48 | 66 | 35 | 85 |

| DPP100/40 | 100 | 250 | 40 | 61 | 37 | 70 |

| DPP110/40 | 110 | 280 | 40 | 52 | 33 | 85 |

| DPP120/40 | 120 | 300 | 40 | 42 | 26 | 68 |

| DPP140/34 | 140 | 350 | 34 | 37 | 24 | 58 |

| DPP150/31 | 150 | 380 | 31 | 34 | 26 | 46 |

How to Choose the Right Screen Mesh Count:

Different mesh count is used for different applications in the screen printing process. Mesh count is calculated under how many holes on the mesh each per inch, usually we use T represent the holes quantity per centimeter. For example: 305mesh has 305 holes per inch, with 120 holes per centimeter. The higher the mesh count, the finer the threads and there are more holes. The size of the mesh is related with how detailed your image is and how thick the ink you are using is. If you want to print an image with extremely high detail, the fine mesh (high count mesh) is good choice. And if you are using a thicker ink, the low count mesh is better choice. The follosing is the general outline of what sizes to use for certain types of printing.

For the 110mesh (43T) is great for block text letters and larger spot color designs. For white falsj plates we suggest this size too, as you will only have to make one print impression for many times to save production time. For 156mesh (61T) as the finer mesh can offer you some higher detail ability in your image but it also lays down a little thicker layer of screen printing ink. Lower mesh counts such as 40mesh-86mesh are used for shimmer and glitter inks. 200mesh and 230mesh are used for finer detailed images and thinner inks. These mesh sizes can hold larger half tone dots but are not recommended for four color process prints or fine detail half tone printing. For graphic and solvent based silk screening inks that are much thinner should be used with these mesh sizes. For soft feel on the shirt can print use these higher count mesh which less ink trough the screens. 305mesh is used for extremely high detail textile printing and fine halftone four color process and simulated process prints. Fine half tone dots need high fine detail mesh in order to hold and expose on. Higher meshes such as 355mesh, 380mesh, and 420mesh are used mainly for graphic printing with UV inks. UV inks are extremely thin and many times are used for high detail printing on signs, banners, or CD’s. Using a higher mesh allows the automatic printers used in UV printing to regulate the amount of ink passed through the screen.

Why Choose Yellow Mesh:

We recommend that you chose a yellow mesh if you are choosing a mesh count of over 155. Died (yellow) mesh exposes much better than white mesh in the higher counts because it blocks light conductivity through the threads. White mesh is more cost effective and works just as well on lower mesh counts. We do however offer both white and yellow mesh in a variety of different sizes.

Features & advantages:

- 100% monofilament Polyester mesh yarn imported from Japan, Swiss or Jintong in China

- Germany Warping machine

- P7100 weaving machine

- Color: White, yellow, black, etc, white and yellow is the normal colors

- Width: 50CM-373CM

Production Process:

- Purchase material – Check the physical properties of the yarn(tensile strength, color, tolerance, even or not, etc)

- Warping – After finished yarn inspection, then do warping with the Germany warping machine

- Threading the heddles – the yarns will be drawn one by one

- Drawing the reed

- Weaving

- Washing

- Heat setting

- Initial Inspection

- Stock

- Second Inspection before cutting into small rolls

- Third Inspection during printing before packing

- Fourth Inspection after packing. (in random)